Dangers, Deaths, Injuries and Perceptions in the Construction Industry

The Australian construction industry is the third most deadly with around twice the average fatality rate and is ranked fifth for causing serious injury, according to Safe Work Australia (SWA).

Despite improvements in recent years, 2012/13 financial year data shows labourers in Australia suffer the highest incidence of serious injury of any profession. Tradespeople followed in third place. During the five years to 2011/12, falls from heights (buildings, ladders and scaffolding) were the most deadly. Coming second is deaths from vehicles and lastly deaths from being hit by falling objects.

The most common cause of construction work-related injuries in 2009/10 were cuts and open wounds (31%), sprain/strains (21%), chronic joint or muscle conditions (16%) and fractures (10%).

SWA research found that the most common causes of these injuries was lifting, pushing or pulling an object (30%), hitting or being hit by an object (31%) and falling from height (15%).

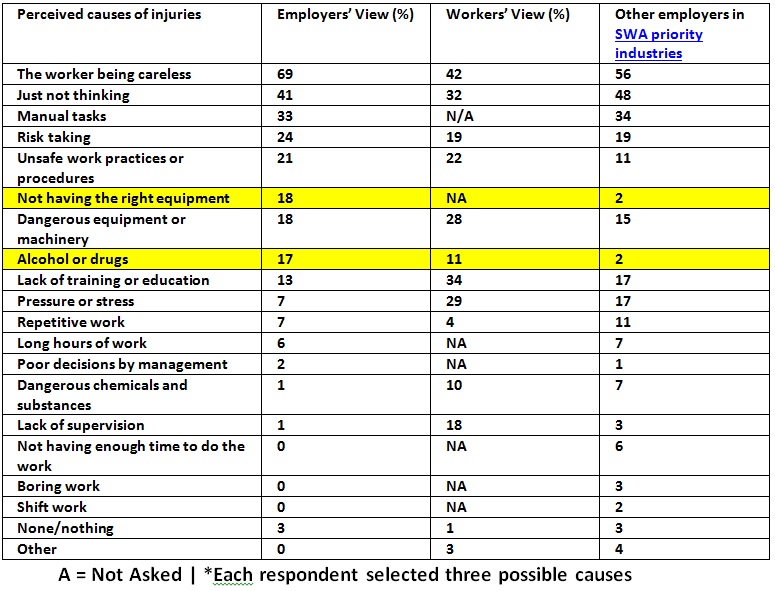

Worryingly, two major contributing factors of injury are not having the right equipment and the use of drugs or alcohol.

With a safe work culture proven to save lives and money, here’s a list of some of the most common incidents and how to help prevent them.

Falls from heights

Falls are the most common cause of death and third most common cause of injury. A range of preventative measures should be used. This includes handrails on all scaffolding and elevated work platforms, as well as the provision of quality fall arrest harnesses.

Cuts and open wounds:

The most common work-related injury in the construction industry are cuts and open wounds. Safety measures should include using high quality tools and machinery with guarding and braking, training staff and providing cut resistant gloves fit for purpose (eg wet or oily).

The incorrect glove type may increase the dangers due to a lack of control or a lack of comfort leading them to not wear gloves at all.

Airborne Hazards

Worryingly, 16% of workers in the construction industry exposed to airborne hazards such as dust, gases, vapours or fumes reported that they were not provided with any control measures – including PPE. A further 6% had engineering controls such as extractors but no PPE.

The provision of masks and respirators is critical to the health, safety and morale of workers. Further measures should include ventilation systems and reducing time spent in places with airborne hazards.

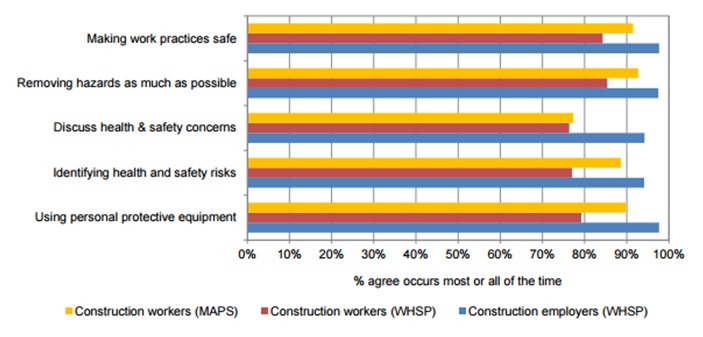

Safety practices in the construction industry. MAPS / WHSP represent different surveys. Source Safe Work Australia 2015

Vibration

With 55% of construction workers saying they are exposed to vibration from power tools and machinery, employers are responsible for minimising their risk of the potentially dangerous “hand arm vibration syndrome” (HAVS).

However 22% of those exposed to vibration at work reported that they did not receive any control measures.

PPE measures include vibration resistant gloves. Other measures include vibration dampeners, vibration absorbing seats, purchasing products with less vibration and worker training.

Noise

Dangerous levels of noise is common on a construction site. Despite this, 8% of construction workers are not provided any control measures including PPE such as earplugs or ear muffs.

Other measures should include training and signage, rotating jobs, placing noisy equipment in an isolated room, and purchasing quieter machinery.

Chemicals

Around 45% of construction workers are exposed to chemicals such as cleaning agents, degreasers, paint and solvents. However 12% of workers did not receive PPE such as protective gloves and clothing, nor control measures such as warning signs, washing facilities and training.